Crankshafts are the major rotating parts of an engine that are positioned on a connecting rod and can convert the connecting rod's up and down movement into a circular movement. In the crankshaft production process, a billet of acceptable size is typically heat treated to the required forging temperature before being successively pounded or pressed into the required shape by pushing the billet between a pair of dies under high pressure. If complex shapes or extreme deformations are to be created, more than one set of dies is required to complete the task and obtain the desired shaping.

Crankshafts can either be made from Casting process or Forging process.

Unique Forgings is one of the most popular Forging Manufacturer Companies in India producing forged components.

How Forged Crankshaft has an upper-hand over Cast Crankshaft?

●Forged Crankshafts are stronger:

Forged crankshafts are stronger and more durable than cast crankshafts because of the hot and cold working that a cast crankshaft lacks. Forging ensures that parts and components are stronger.

Unique Forgings is the leading Steel Forging manufacturer in India.

●Forged Crankshafts are reliable and inexpensive:

There are a number of possible casting defect that can seep into your crankshaft. Because hot working degrades product attributes such as resistance, ductility, and strength, crankshafts made by professional forged crankshaft producers are more reliable and less expensive because they require less controlled operations and inspection.

●Forged Crankshafts respond uniformly to the heat treatment:

To avoid alloy segregation, castings require control over the melting and cooling processes. As a result, the heat treatment has a non-uniform response, which can impact finished products. Forged crankshafts respond reliably to heat treatment, resulting in greater dimensional stability.

If you are looking for the top quality Forged Crankshaft, contact Unique Forgings today to place your order.

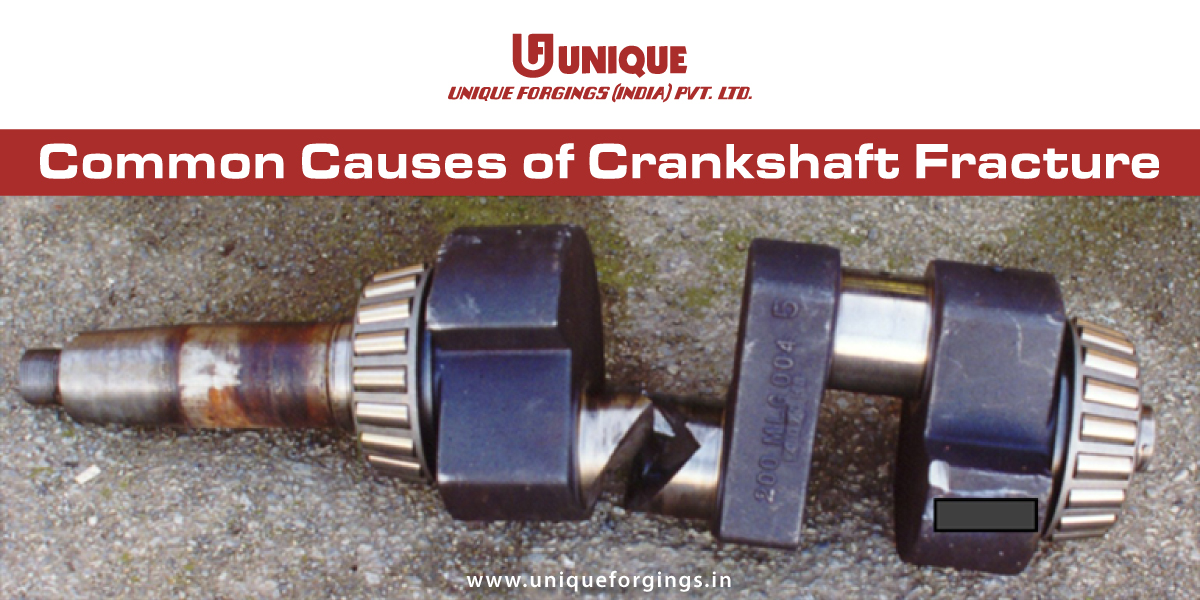

Common causes of crankshaft fracture:

- Individual users, due to poor engine oil selection, or failure to pay attention to cleaning and replacement, oil long-term use of metamorphism; Serious overloading, super hung, resulting in engine overload operation for an extended period of time and the appearance of tile burning failure. The engine crankshaft has suffered significant wear and tear as a result of tile burning.

Users could choose to fix a damaged crankshaft for standby use or replace it with a new one. Some users are more concerned with cost and time, and may seek out a small manufacturer in their area to repair, surfacing welding, processing, entire heat treatment, and grinding on the crankshaft's major wear part. Changes will occur at the connecting round corner of the crank pin, main journal, and crank arm round as a result of repair methods and process difficulties, creating local stress concentration.

Because the crankshaft is comprised of 45# steel and it is manufactured by the closed die forging process, surface welding will modify the metallographic texture. As a result of the preceding two circumstances, the crankshaft will suffer a second fracture.

Unique Forgings manufactures the best-in-class Forged Crankshaft in India.

- After engine repair, overload ultra hang without passing through the run-in phase and overload working for an extended period of time will cause crankshaft overload to exceed the allowable limit.

- Surface welding in crankshaft repair damages the crankshaft's dynamic balance, and a loss of balance calibration leads the engine to vibrate excessively, resulting in crankshaft fracture.